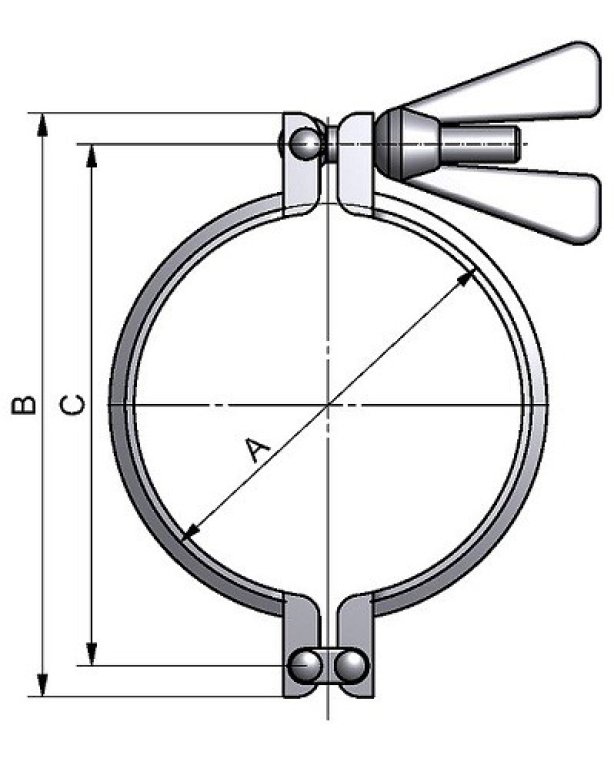

Zaciski

| DN | A | B | C | D | Article 304 |

|---|---|---|---|---|---|

| 25.0 | 25.0 | 25.0 | 188910121 | ||

| 34.0 | 34.0 | 34.0 | 188900201 | ||

| 50.5 | 50.5 | 50.5 | 188911001 | ||

| 64.0 | 64.0 | 64.0 | 188912001 | ||

| 77.5 | 77.5 | 77.5 | 188912121 | ||

| 91.0 | 91.0 | 91.0 | 188913001 | ||

| 106.0 | 106.0 | 106.0 | 188900801 | ||

| 119.0 | 119.0 | 119.0 | 188914001 | ||

| 130.0 | 130.0 | 130.0 | 188914121 | ||

| 155.0 | 155.0 | 155.0 | 188915121 | ||

| 167.0 | 167.0 | 167.0 | 188916001 | ||

| 183.0 | 183.0 | 183.0 | 188916581 | ||

| 217.4 | 217.4 | 217.4 | 188918001 | ||

| 233.5 | 233.5 | 233.5 | 188918581 | ||

| 268.0 | 268.0 | 268.0 | 188926851 | ||

| 319.0 | 319.0 | 319.0 | 188931931 |

Article properties

| According to | DIN 32676 |

| Field of application | Food, Chemistry & Farma |

| Maximum pressure of 140°C when right gasket is used | Pipe size 6,35-42,4mm (25Bar) - Pipe size 48,3-219,1mm (10Bar). |

| Material According to EN 10088-1 | 304/1.4301 - 316L/1.4404- 316L/1.4435 |

| Use tube Material | EN 10357 Serie A, B, C and D and DIN11866 |

| Finishing general | Forged / Turned internal Ra<0.8µm, external Ra<1.6µm |